|

|

|

| |

|

|

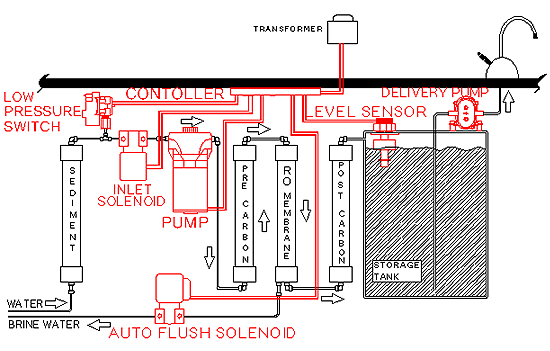

- Low Pressure Switch(LPS)

-

Should be installed

after the sediment filter and before

Inlet Solenoid and Pump. Uses

a micro switch to signal when inlet

pressure is below 5psi. Used

to prevent the system from continuous

operation that can happen when the

water supply is stopped. Without

the LPS, if the inlet supply is

interrupted the system will continue

to operate because the storage tank

will not fill (not making water)

and therefore not provide an 'OFF'

signal for the system.

- Inlet Solenoid

- The Inlet, or Main Solenoid opens

at start of filtration cycle and closes

at end of filtration cycle.

- Pressure Boost Pump

- Used in areas where the source

water pressure is below 50psi. The

Pressure Boost Pump provides a constant

70+psi for optimum membrane performance.

Pump model varies depending

on membrane specification.

- Controller (PCB)

- The PCB Controller integrates all

the electronic functions of the system.

It operates the system based

on two sensor inputs, typically the

Low Pressure Switch and Level Sensor.

Based on signals from these

two sensors, the PCB opens and closes

the Inlet Solenoid and Auto Flush

Solenoid, and starts and stops the

Pressure Boost Pump.

- Float Level Sensor

- In the case of an atmospheric tank,

a level sensor must be used to indicate

tank level to start and stop the system

operation. Float Level Sensors

are available in side mount or vertical

mount. Vertical mount can be

either Dual or Single Float.

- Auto Flush Solenoid

- The Auto Flush Solenoid is controlled

either by the PCB or the Auto Flush

Circuit. When the solenoid is

closed the brine passes through an

orifice that is sized according to

the membrane specification which restricts

the brine flow for normal operation.

At the beginning of each filtration

cycle, the Solenoid will open allowing

free brine flow to flush the membrane

surface.

- Delivery Pump

- The Delivery pump is

used to transfer water from the holding

tank to the point of use. Deliver

pump operation is controlled either by

a High Pressure Switch attached in between

the pump and the spigot, or by an on/off

switch on the spigot.

|

|

|

|

|

|

|

|

|

|